My Latest Projects

I have worked on multiple projects projecting the latest technologies and algorithms. Shown below are some of

those projects. For the source code please check out my page at GitHub!

Design Optimization

Built a model for the optimization of the design parameters of a windmill turbine blade. The accrued results proved an optimized design with an efficiency improvement of 1.2 % of power output.

AUTONOMOUS DRIVING

Implemented machine learning, tracking controls and lane detection on an RC car for autonomous driving. The developed model proved efficient for image detection and self-driving.

Robotics

Developed an arduino controlled robotic arm to perform material movements for industry purpose. High level sensor fusion & ML was implemented for a robust task performance.

UDACITY-SELF DRIVING

In this Nano-degree program from Udacity, I learnt and implemented the techniques of the cutting-edge robotics, automation & ML for transformational technology.

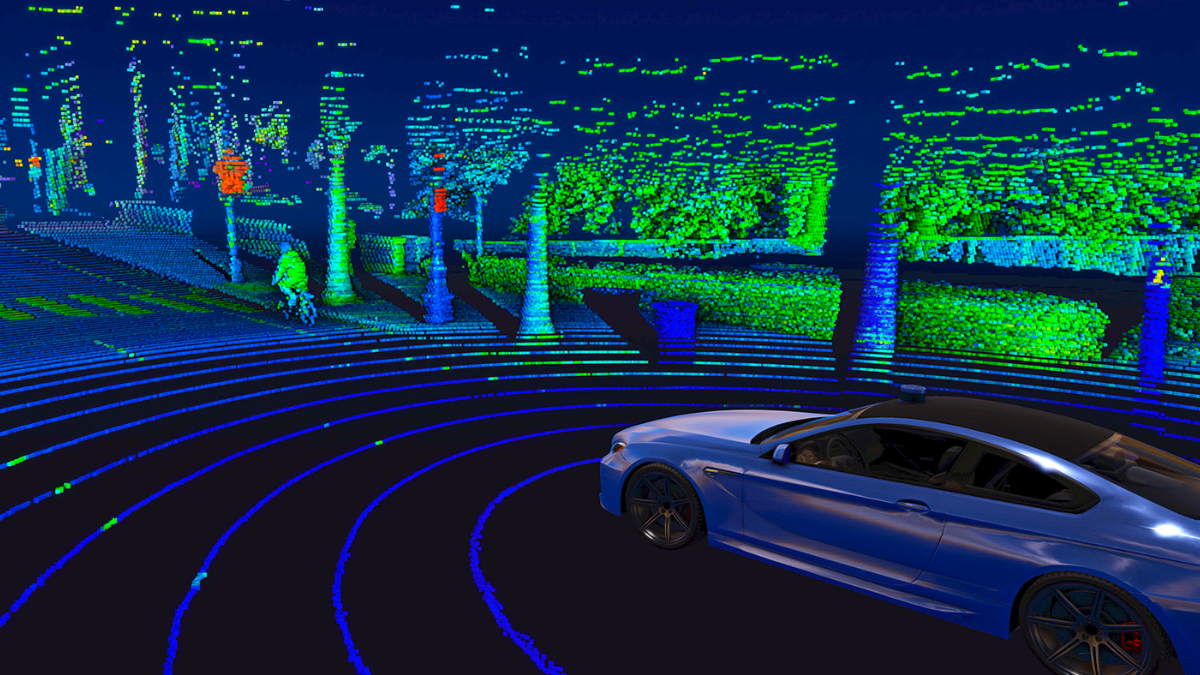

Mapping using sensors

Generated robut occupancy grid map for navigation and path planning using lidar, range sensors and camera. The algorithm has a confidence interval of 0.94 with the perception model.

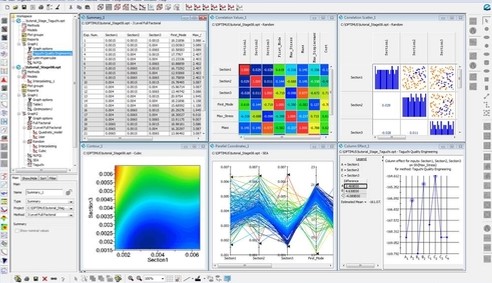

Statistical data analysis

Successfully Extracted and labelled data for statistical analysis and dashboard creation. The data from PLC are used to develop HMI for the industrial automation & controls.